Mission

VTech's sustainability mission is to design, manufacture and supply innovative and high quality products in a manner that minimises any impact on the environment, while creating sustainable value for our stakeholders and the communities in which we operate.

Approach

In order to achieve the sustainability vision and mission, VTech has developed a 5-year Sustainability Plan 2025, focusing on increasing the use of sustainable materials in our products, recycling our products in a responsible way, increasing the use of renewable energy and reducing the natural resources consumption in our production process, as well as stepping up our efforts to use more eco-friendly transportation modes in our supply chain management.

5 Key Focus Areas of VTech's Sustainability Strategies

- Governance & Business Ethics

- Product Responsibility and Value Chain Management

- Environment

- Our People

- Society

Product Responsibility and Innovation

VTech strives not only to provide high quality products and comply with the highest product quality and safety standards, but also incorporate sustainability concepts into product design for the well-being of our customers and the society. A Supply Chain Management System is also in place to ensure the implementation of sustainable supply chain practice throughout the company.

VTech strives not only to provide high quality products and comply with the highest international and local quality and safety standards, but also incorporate sustainability concepts into product design in order to enhance the well-being of our customers and benefit the society. Our management approach continues to focus on two key management principles – “Design for People” and “Design for Excellence”.

Design for Quality

We have implemented a stringent quality control system, from all materials, components, machines and equipment, operational techniques and methods to the final products assessment, to ensure that the use of all materials and manufacturing processes are compliant with both international and local standards and requirements.

VTech Quality Control System

Upholding the highest quality standards of our products, all VTech CMS’s manufacturing facilities are certified with ISO9001. VTech has implemented a comprehensive quality management system framework to set up quality assurance policies and procedures to address the product quality and reliability on a regular basis, as well as improve the work efficiency

CMS Quality Laboratories

To improve the quality, durability and performance of our products, we have set up our in-house product quality and reliability validation laboratories (labs) at the manufacturing sites of our product lines. All our products must go through reliability tests during different design stages. The comprehensive tests provide data for our engineers to improve the quality and reliability during the stages of production, transportation, storage and throughout the intended product life cycle under a wide range of use conditions.

Environmental Protection

VTech has developed "Climate Change Strategy" to assess and address the potential impacts of climate change on its sustainable growth through the implementation of high performance production chain, green manufacturing and sustainable logistics practices. We also have policies in place to ensure that our operations are compliant with all the relevant environmental, legal and statutory requirements.

VTech has developed a high performance production chain to maximise our resources efficiency and improve the productivity while maintaining a green manufacturing and logistic practice. As an environmentally conscious company, VTech strives to operate its manufacturing processes and facilities in a manner that minimises the impacts to the environment, and ensure that our operations are compliant with all the relevant environmental, legal and statutory requirements. By implementing the high performance production chain, we have improved our resources efficiency and productivity while maintaining our green manufacturing practice. Through the adoption of the green logistic management approach, and choosing the most eco-friendly transportation mode for delivering our incoming materials from suppliers and outgoing products to our customers, we have also further reduced our GHG emissions.

The key environmental impacts from VTech’s operations relate to energy and water consumption, waste generation and logistics. We are committed to minimizing the potential environmental impacts from our operations with the following principles:

- Comply with all relevant environmental, legal and other statutory requirements

- Maintain an Environmental Management System in line with the requirements of ISO 14001

- Quantify and monitor the significant environmental impacts of our activities, products and services and set specific targets for improvement where appropriate, and review these annually

- Integrate environmental objectives into our business decisions in a cost effective manner

- Require all staff to address environmental responsibilities within normal operating procedures

- Enhance awareness of environmental and resource efficiency issues amongst our customers, suppliers, staff and stakeholders through improvement projects and programmes in the respective areas

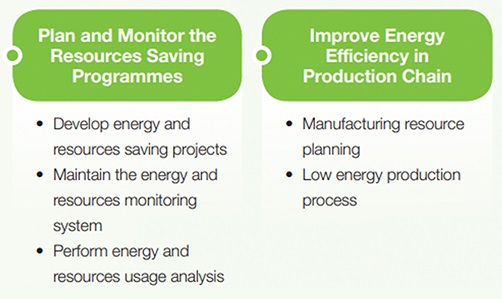

Energy and Electricity

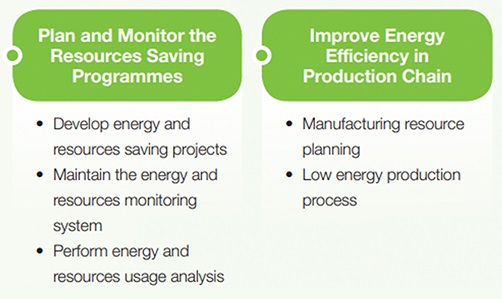

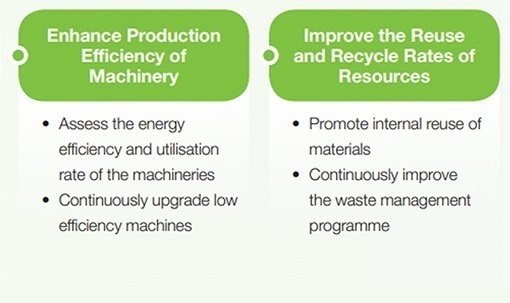

Energy and Resources Management Our Resource Efficiency and Conservation Team (RECT) at each manufacturing site has been making significant achievements in monitoring the energy saving progress through the implementation of our resources saving projects. The RECT includes our production floor managers, equipment technicians and internal energy analysts. They ensure our resources are well utilized at the operational level by focusing on the following areas:

Carbon Emissions

The use of energy is the major contributor of both direct and indirect emissions in VTech. With the target of minimising the environmental impacts, our energy conservation programmes and activities have made a notable reduction in the energy consumption and thus the carbon emissions. As a result, most of our energy saving activities are focused on reducing electricity consumption.

Water

Clean water is a valuable resource, which VTech is committed to conserving. We only use water supplied from municipal sources and do not have any on-site wells or boreholes. The wastewater is mainly generated from workers’ living activities. To control water pollution, VTech continuously reinforces wastewater treatment by strictly following ISO 14001 and local government requirements, upgrading wastewater treatment system, carrying out measurements of required items, in order to meet the wastewater standards.

Waste and Recycling

VTech aims to operate our factories with maximum resources efficiency by minimizing the materials used throughout the manufacturing process and increasing the recycling rate and the use of reusable materials. We keep track of the materials that we use, aiming to minimize unnecessary waste of materials from the product design, downsize the PCB rims and reduce the use of packaging materials. Throughout our production, we have also installed machineries and devices to further reduce the consumption of excessive parts and materials.

In order to increase our recycling rate and maximize our resources efficiency, we have set up recycling centres at all our manufacturing sites. Recyclable materials are recycled at material recovery centres. We also work closely with our suppliers by returning our plastic recyclables to suppliers for reuse.

Our approach in Hazardous Waste Management Scheme is to reduce the environmental impact that is caused by the use of hazardous chemical and to deal with the hazardous substance responsibly by controlling the use of these chemicals and strictly following the Management of Solid Waste Disposal Ordinance released by the Central People’s Government of the People’s Republic of China.

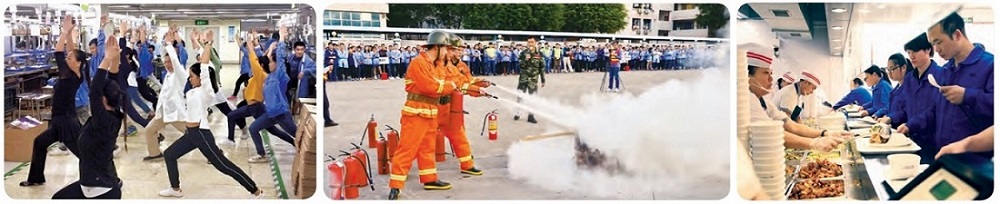

Workplace Quality

VTech aims to provide a supportive, pleasant and healthy workplace for our employees, and to foster a caring community in our working environment. We care for our employees and recognize that having good staff relations and a motivated workforce play a vital role in the company's efficient operations.

VTech aims to provide a pleasant, supportive and healthy workplace for our employee, and to foster a caring community in our working environment. We care for our employees and recognize that having good staff relations and a motivated workforce play a vital role in the Company’s efficient operations.

All our existing VTech assembly and plastic factories are certified with the Occupational Health and Safety Management Systems (OHSAS 18001 or ISO 45001). Our CMS assembly factories are also certified with Social Accountability (SA 8000) certification and ELPs with ICTI Ethical Toy Program compliance certification. These external verified certifications validate our compliance with local laws and high quality working conditions.

4 Key Values of Our Human Resources Management Policy

Labor and Human Rights Policy

VTech is committed to respecting the labour and human rights of all our staff through the following principles, which are clearly stated in our human resources management policies:

- Freely Chosen Employment

- No Child Labour

- Freedom of Association

- Anti-slavery

- Benefits and Wages Exceed Minimum Legal Requirement

- Overtime Policy

- Equal Opportunity and No Discrimination Policy

- Zero Tolerance of Harassment and Abuse

- Workplace Safety

Sustainable Operating Practices

VTech has policies and systems in the areas of Business Continuity Management, Supply Chain Management and Climate Change Strategy to ensure that we have a sustainable operating practice throughout the Company.

VTech has three core policies and systems to ensure that we have a sustainable operating practice throughout the Company. We have “Business Continuity management” programme to identify and mitigate our potential operational risks, and increase our resilience capability to resume our operations in an effective and timely manner. For the supply chain management which is crucial for our sustainable operations, we have a well established “Supply Chain Management System” to monitor the quality of our suppliers as well as their environmental and ethical performance in accordance with VTech’s CSR requirements. As an environmentally conscious and sustainable company, VTech also recognises that climate change could create uncertainties in our business development. We have developed our “Climate Change Strategy” to assess how climate change could affect our business operations, and minimise the potential impacts on our sustainable growth. We continuously review our environmental management approach and carbon reduction programmes in order to manage our carbon emissions in the supply chain and daily operations.

Sustainable Supply Chain Management

A well established Supply Chain Management System and a good procurement practice are crucial for our sustainable operations. VTech has a Supply Chain Management System in place to monitor the quality of our suppliers as well as their environmental and ethical performance. We are committed to managing our supply chain in a socially and environmentally responsible manner and sourcing from approved suppliers who meet VTech’s CSR requirements.

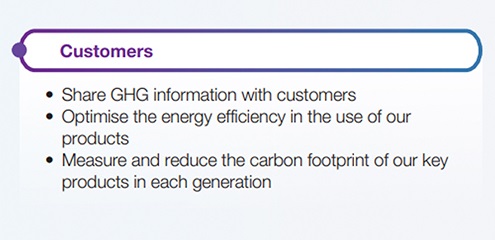

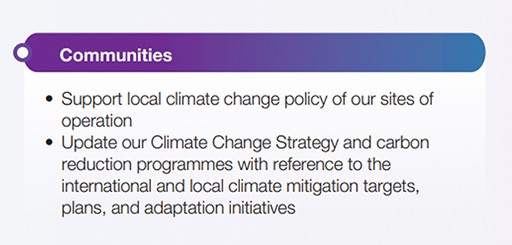

Climate Change Strategy

Climate Change Strategy In 2015, the United Nations Development Programme announced the Sustainable Development Goals at the Paris Climate Conference which became effective in 2016. The agreement addressed the common standards and set ambitious goals for downsizing the global carbon emission amount to mitigate the environmental impacts caused by climate change. The Chinese government also announced its carbon pledge, aiming to limit the carbon dioxide emissions by 2030 and reduce its carbon intensity by 60-65% from 2005 level. VTech has the major manufacturing sites located in China. As an environmentally conscious and sustainable company, we are committed to taking the responsibility in the GHG reduction and aligning our sustainable growth with the national and international climate change agenda.

Society and Community

VTech uses its expertise and resources to support the communities in which it operates, focusing on supporting people in need, collaborating with local charities, providing training opportunities for young people, nourishing an innovative environment and developing a healthy and green community.

5 Key Areas for our Community Involvement Developed in FY2015.

Since the establishment of VTech’s voluntary teams in different manufacturing sites and global offices, we have participated in various voluntary events, and created a strong social network to assist and support the people in need. We also encourage our employees and their families to participate in our volunteering activities, bringing positive impact to the families and society. Our China and Hong Kong voluntary teams frequently participate in various types of voluntary services including visiting elderly homes and children hospitals, and supporting crowd control at community events. Besides being presented with the “Heart to Heart Company” by the Hong Kong Federation of Youth Groups, VTech has also been awarded the “Caring Company” by The Hong Kong Council of Social Service for the tenth consecutive year in recognition of our continuous contribution to the Hong Kong community through various charitable activities. In FY2018, we were awarded Business for Sustainability Logo, demonstrating our significant progress to integrate sustainable practice across our business operation. These awards are a great encouragement for our voluntary works for the community.