Vtech CMS is the name behind many world-class companies in the industrial filed for years. We support each client in the development and contract manufacturing of a wide range of complex and technologically advanced industrial products.

-

Industries Industries

-

Industrial Electronicslearn more

-

Health Care & Medical Devicelearn more

The manufacturing of home health care, personal well-being, and other medical products (non-patient-connect) has been one of the growing product application focuses for VTech CMS since the late ‘90s.

-

IoT & Communication Technologylearn more

VTech CMS handles communications and IoT device manufacturing for clients from numerous different industries. Our goal is to develop & manufacture products that bring practical improvements in our world.

-

Energy Management Devicelearn more

The increasing focus on environmental issues is creating a huge demand for Energy Management Products. VTech CMS has proudly served global OEMs for more than 20 years. Our automation implementation throughout the manufacturing process supports our flexible processes and high-quality production.

-

Hearable & Wearable Devicelearn more

VTech is the manufacturer of the world's first smart TWS (True-Wireless) headset and has more than 15 years of experience on hearables for both consumer and commercial markets. VTech CMS supply more than a million units of hearables to the global market.

-

Professional Audio Equipmentlearn more

For over 20 years, VTech CMS has been the trusted manufacturing & product development partner of many premium professional audio brands. Our R&D and VE (Value Engineering) professionals develop innovative and high-quality professional audio products for our clients.

-

-

Capabilities Capabilities

-

Innovation & Value Engineeringlearn more

VTech is a one-stop-shop solution provider delivering technical support from initial product development to mass production. By applying Lean Process concept, our engineering and design teams excel at offering a range of value-added services.

-

Supply Chain Managementlearn more

VTech CMS maintains a robust Supply Chain Ecosystem with excellent management on supplier quality, cost competitiveness, best-in-class flexibility as well as business sustainability.

-

Quality Systemlearn more

VTech CMS has an established, integrated Quality Model, which upholds our commitment to providing the highest quality manufacturing services. We strictly adhere to all industry standards but also have the flexibility to support our client’s individual quality requirements and procedures.

-

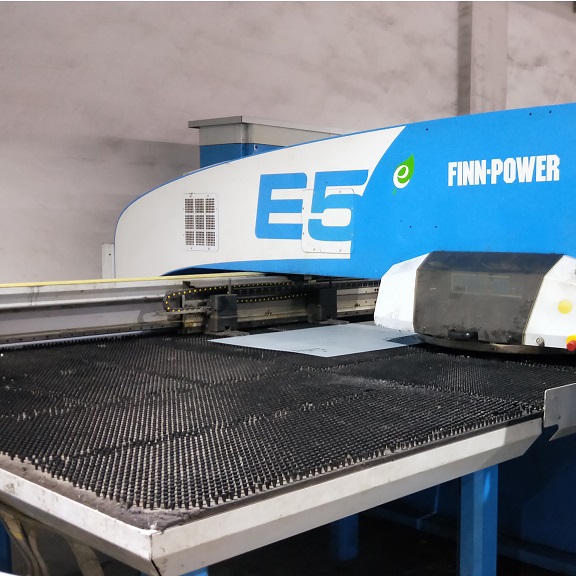

Advance Manufacturinglearn more

VTech CMS delivers turn-key manufacturing services from printed circuit board assemblies (PCBA) to full box builds and complete systems integration. We have implemented Lean manufacturing solutions which are suitable for diverse mix of products.

-

-

Facilities Facilities

-

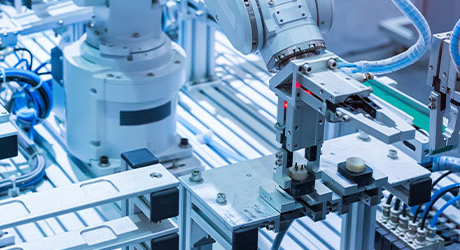

Automation & Industry 4.0learn more

VTech CMS continues to enhance automation & smart technologies implementation moving toward to the world of Industry 4.0. Automated, smart warehouse, fully automated testing solutions, Manufacturing Information System (MIS) with big data analysis.

-

Reliability Testlearn more

Our extensive reliability test lab performs a wide range of product reliability testing that meet established benchmarks in a variety of industries.

-

Locationslearn more

VTech offers high quality manufacturing & project management service covering PCBA, box build, systems integration, New Product Introduction (NPI) services for wide range of industries in global locations.

-

-

NPI Centre NPI Centre

-

About Us About Us

-

Vision & Missionlearn more

To provide world-class Electronic Manufacturing Service to global clients in a manner that minimizes any impact on the environment, while creating sustainable value for its stakeholders and the community.

-

CSR & Sustainabilitylearn more

VTech's sustainability vision is to create sustainable value for the lives of people and protect the planet for the future generations.

-

Our Storylearn more

Founded in 1993 as a subsidiary of VTech Holdings Limited (HK303), VTech Contract Manufacturing has continually outperformed other manufacturers in the Global EMS Industry. VTech CMS is currently ranked 25th overall among worldwide contract manufacturers while also being ranked the No.1 EMS provider in the Hong Kong region.

-

-

Media & Resources Media & Resources

-

Resourceslearn more

Download the company's internal resources.

-

Newslearn more

Stay in touch with VTech and find out what’s new.

-

-

Supplier Relationship Supplier Relationship